Vinh Long pottery is a manifestation of the Mekong Delta’s aesthetic – traditional culture. Pottery is made of clay, and fuel is rice husk, a byproduct of agriculture that is very popular in the Mekong Delta, so it can be delivered in huge amounts and at reasonable prices to production facilities on a consistent basis. The pottery has the distinctive color of natural red and white veined alum clay after burning. Furthermore, some firms are researching and developing a variety of products such as cement potterys, ancient imitation potterys, glazed ornamental potterys, and so on in order to expand the product line for Vinh Long red pottery village.

Looking back on the establishment and growth of Vinh Long pottery village

Vinh Long pottery village’s founding period

Vinh Long Red Pottery’s collective trademark was approved by the National Office of Intellectual Property on June 8, 2001, which is good news for pottery manufacturers. As a result, the Vinh Long red pottery sector has through a lengthy development phase. In 1983, the pottery profession was established in Vinh Long, which had previously been the principal location for the production of bricks and tiles. At the time, just one company was pioneering investment in pottery manufacture using long kilns powered by waste wood fuel. However, it wasn’t until ten years later, in 1993, that Vinh Long’s red pottery received an export contract. Vinh Long Red Pottery’s collective mark is a foundation to help the red pottery industry grow in the coming years.

The year 1997 was a watershed moment in the evolution of Vinh Long red pottery. For the first time, three brick and tile manufacturing businesses in Vinh Long city and Long Ho district investigated the production of potterys using conventional circular brick kilns. Because the fuel is also rice husk, pottery manufacture is more efficient and cost effective. The loss rate while firing from more than 50% was lowered to only 10-20%. This creates a new chance for the Vinh Long red pottery sector to grow in quantity and quality while reaching out to the global market.

Vinh Long pottery’s quick development stage

That was a crucial premise for Vinh Long red pottery to swiftly expand after that. By 2002, Vinh Long province had more than 80 pottery production firms, with a peak of 120 enterprises with various large and small production scales. Many major businesses have up to 70 or 80 kilns. Red pottery production has made significant contributions to labor settlement and accounts for a significant share of the value of local industrial production. Vinh Long clay resources have increased in value as a result of business activity.

Discover how to make wonderful terracotta pottery goods.

Clay is necessary for producing high-quality pottery items; temperature is secondary. Clay components are kneaded numerous times via the machine, and additives are added to manufacture “clay blocks” based on the size of the product, using more or fewer “clay blocks.”

When the piece has not been baked and the clay is still soft, the artisan will place it on the turntable to rectify any minor flaws. After that, it will be placed in the kiln, where the artisans will seal the kiln door and burn the rice husks at a low temperature to dry out the product within, before raising the kiln temperature to 850 or 900 degrees Celsius.

The craftsman will open the kiln door and retrieve the items in around 3 to 4 days… Many pottery enterprises still employ fire fuel, which is rice husk, a trait found only in wet rice areas. Pottery manufacture is substantially more cost-effective when rice husks are used for fire. The loss rate while firing from more than 50% was lowered to only 10-20%. This creates a fresh potential for Vinh Long’s red pottery industry to develop in terms of both quality and quantity.

Vinh Long red earthen pottery is distinguished in part by designs paired with the skill of artisans. Each item is handcrafted by artists and has a unique name such as “ca na”, “only”, “round leaves”, “bag jar”, “cup”, “belly cup…”

Can see more products at: Product Page

Vinh Long Pottery has developed excellent social values.

Pottery production has provided jobs for tens of thousands of people while also serving as a training ground for highly trained and motivated craftsmen. The artisan village’s products have been seen in Europe, America, Australia, and various Asian countries, including Korea, Taiwan, Hong Kong, and Japan, and the output is growing. Finding markets, exploiting and restructuring production in the direction of industry, diversifying products, particularly quality and design, is a critical requirement for Vinh Long potterys to expand…

According to the Vinh Long province’s Department of Industry and Trade: “Vinh Long red pottery is partly specific in its designs, demonstrating the talent of the southern granary craftsman, the main feature is that the earthenware products are.” Unglazed fired with rose red color, intermingled with silver-white spots, creating a unique attractiveness for clients from several European countries, America…

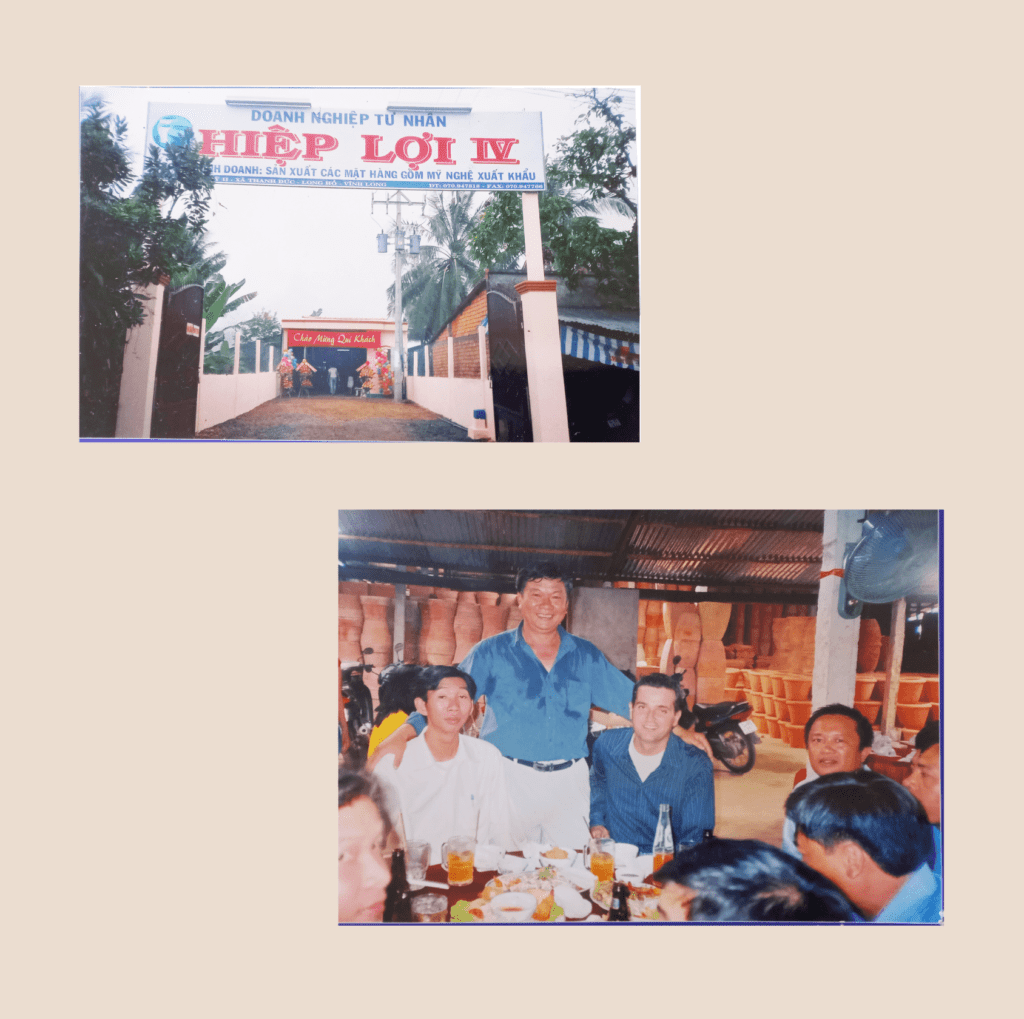

A brief description of the Hiep Loi IV pottery manufactory – a typical production base of Vinh Long Pottery Village

We are happy to be a cerampottery manufacturer that appeared from the early days of Vinh Long pottery village, along with the hometown craft village going through ups and downs, and we have more than 20 years of research and development expertise manufacture of terracotta pottery

With the purpose of becoming one of the leading companies in direct export to the global to raise the value of the Vinh Long pottery market. We constantly try and improve with the slogan “Preserve and develop together”. We highly priority to reach sustainable and long-term cooperation relationships so that we can compete successfully in the pottery market.

Know more about us at: Contact page

Address: 7243+Q58, ĐT902, Thanh Đức, Long Hồ, Vĩnh Long, Việt Nam

Phone: (+84)943150508

Email: dntnhieploi4@gmail.com

Cre: Reference